THE MEMC LAB IS OF STRATEGIC IMPORTANCE FOR THE PROPER FUNCTIONING OF MEMC

|

Video file

|

In addition to recruiting excellent researchers, state-of-the-art research facilities is crucial for conducting groundbreaking research, for collaborating with other knowledge institutions and for training the next generation of civil engineers. Our cutting-edge technology equipment is also available to the business community. |

|

The main lab contains a 1 meter thick steel-reinforced strong floor of 10 m by 15 m, with massive bolts and anchors (tensile capacity of max. 200kN and lateral capacity of max. 100kN) to which meccano-like test set-ups can be attached and the strength, stiffness or fatigue of relatively large construction parts can be tested. Servo-hydraulic cylinders with a capacity ranging from 25kN up to 500kN are the commonly used loading system. |

|

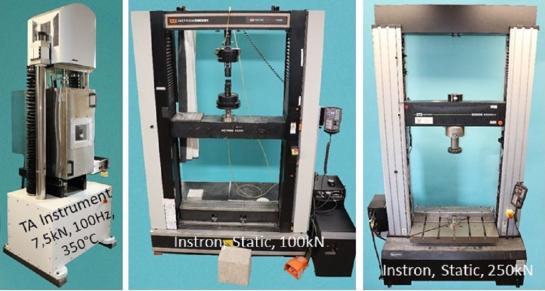

The static and dynamic test benches available at MeMC have a capacity of 7.5kN up to 250kN. For more precise load measurement smaller loadcells (500N & 10kN) are available. Our elaborated set of mounting pieces enables a large number of possible test set-ups like tensile tests with mechanical or pneumatic gripping, three or four-point bending tests, compression tests, shear tests or any other custom-made set-up. Displacements and strains can be monitored using different techniques like Digital Image Correlation (DIC), strain gages, extensometers, LVDTs and CODs. By using an external chamber (0.49 m x 0.49 m x 0.69 m) of our climate chamber, tests can be executed on this test bench between -20°C and 120°C and between 10% rh and 85%. A furnace (up to 350°C) can be used in combination with the 7.5kN ElectroForce for DMA testing. |

|

For biaxial testing we have at our disposal (1) a MTS servo-hydraulic tension-torsion bench with a capapcity of 100kN in tension/compression and 1kNm in torsion and (2) a home made plane biaxial test bench with four independently controlled servo-hydraulic actuators (100kN) providing the possibility to apply different loadings in both directions. Any type of waveform, including spectral sequences of variable amplitude can be efficiently introduced using the dedicated software and control system. Depending on the specimens' stiffness a test frequency of 20 Hz can be reached. |

|

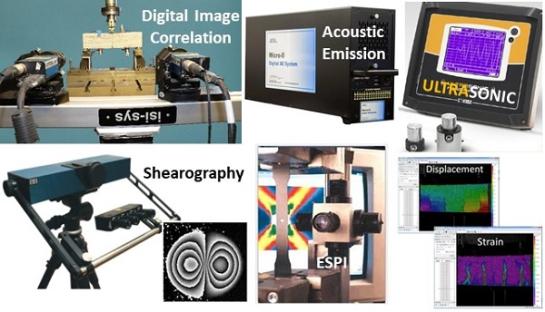

At MeMC several state-of-the-art measurement systems are available for monitoring the applied loads, the displacements/strains and the occurring damage mechanisms during testing. Besides the more convential techniques like strain gages, extensometer, LVDT's, etc., we gained extensive experience in using full-field optical techniques like ESPI, Shearography and the very versatile Digital Image Correlation (DIC) technique. |