INNOVATION IN SERVICE OF SUSTAINABILITY

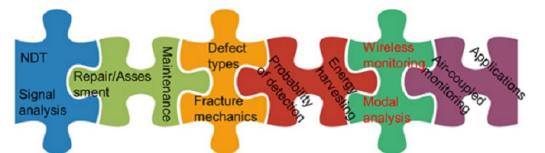

Integrity and safety of infrastructure is a serious concern for society. Structural failures lead to casualties and economic losses, threatening societies’ well-being. Furthermore, longevity of the infrastructure directly supports sustainability saving valuable resources. Monitoring the condition of a structure allows to take decisions about usage, maintenance and repair based on engineering criteria contributing to a long, safe operational life. SHM can be regarded as a tool or a process, that uses in-situ sensing devices to detect damage and in general supply information about the health of a structure. It may involve the observation and analysis of the data from a system using continuously or periodically sampled responses to follow changes to the material or structure. SHM is a very diverse topic combining a variety of other disciplines.

|

|

|

NON-INVASIVE MONITORING OF CURING OF CEMENTITIOUS MATERIALS

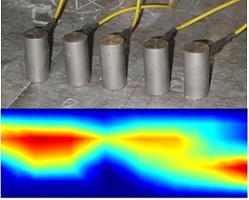

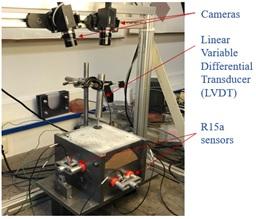

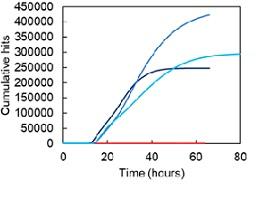

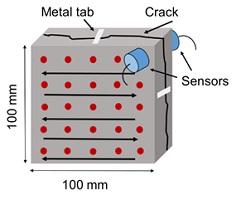

Curing of cement is a relatively short but crucial period for the longevity of concrete structures. Several overlapping processes take place like settlement and shrinkage, shrinkage cracking, temperature variations due to hydration reaction, formation of hydrates and hardening. Monitoring of all of them is extremely difficult through traditional point measurements of displacement (like linear variable differential transducer, LVDT) or very expensive and cumbersome (like nuclear magnetic resonance, NMR). These processes emit low energy acoustic signals that can be recorded by piezoelectric Acoustic Emission (AE) sensors attached to the external surface of the concrete container. AE signals can be separated because of distinct characteristics (frequency, amplitude, duration etc.) and the classification can be enhanced by pattern recognition approaches. Below a cumulative AE activity history for a reference concrete specimen and one containing superabsorbent polymers (SAPs). The internal curing offered by the SAPs is easily detected between 11 and 45 h after mixing by the rich acoustic activity, thanks’ to the sensitivity of AE sensors. ConcreteCube Concrete cube during curing in metal mold with AE sensors and DIC cameras AE_Cube AE activity during curing of concrete with and without internal curing admixtures (SAPs)

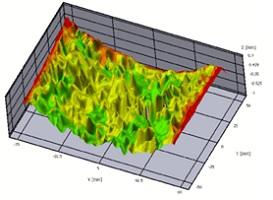

In addition to AE monitoring, DIC cameras provide a stereoscopic view of the top surface and allow a global monitoring of settlement and shrinkage, see figure on the right showing the concrete cube during curing in metal mold with AE sensors and DIC cameras.

Relevant indicative literature:

- doi: 10.3390/s20102959

- doi: 10.1016/j.acme.2018.10.003

- doi: 10.1016/j.cemconres.2019.105964

Concrete cube during curing in metal mold with AE sensors and DIC cameras |

AE activity during curing of concrete with and without internal curing admixtures (SAPs) |

|

NON-DESTRUCTIVE EVALUATION OF SELF-HEALING

Self-healing of concrete is a beneficial approach since it allows local mechanical regain as well as sealing of the crack from external deleterious agents. Self-healing can be promoted by different additives, one type of which is the superabsorbent polymers (SAPs) that can store water and promote further hydration and precipitation of calcium carbonate closing the crack and restoring the mechanical properties of the material.

Traditionally, the evaluation of self-healing is conducted by mechanical loading which is destructive. On the other hand, X-ray tomography cannot evaluate the stiffness of the healing products, while microscopic observation applies only to the surface.

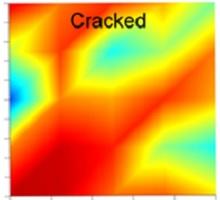

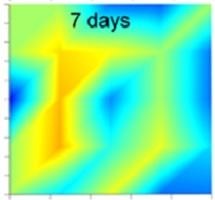

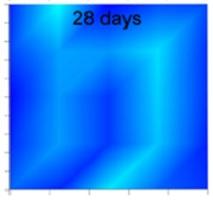

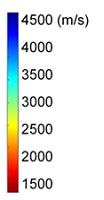

Our approach involves ultrasound that is applied both through the thickness and on the surface. A full mapping of the cross-section allows evaluation of the degree and uniformity of healing and monitoring through time. The technique can be applied in large scale with suitable manipulation of the applied frequencies. When the geometry does not allow access to both sides, surface ultrasound can be applied while varying the frequency, information on different depths is obtained. Combination with elastic wave simulations allows also for the first-time evaluation of the actual stiffness of the healing compounds. The next step is the air-coupled scanning station that is being built.

|

|

|

|

|

MULTIMODAL MONITORING OF LIGHTWEIGHT SANDWICH STRUCTURAL ELEMENTS

Cementitious sandwich structures consist of two facings and an insulating core. While this structural type brings strong advantages in terms of weight, consumption of less materials (and cement in particular), being not prone to corrosion, it may exhibit different fracture modes compared to classical well-researched reinforced concrete. Defects may appear even from production, like debonding between the core and the facing, while during operation a number of additional modes can be activated, like stress and freeze-thaw cracking, pull-out of the reinforcing textile. A monitoring system for quality control after manufacturing, as well as for damage inspection during operation is of paramount importance in a holistic cradle-to-grave approach.

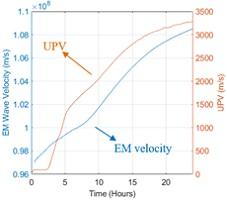

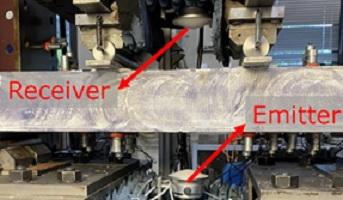

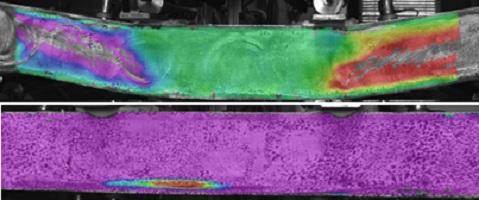

The MeMC department in collaboration with ETRO (Electronics department of VUB) researches on the combination of elastic (UPV) and electromagnetic waves (EM). Ultrasonic transmission and velocity targets the stiffness development during curing, while millimeter waves (EM) antennas are sensitive to the hydration reaction. During loading, acoustic emission (AE) detects and classifies different damage types while transmission of electromagnetic waves allows very precise monitoring of the creation and development of interphases (Fig. 2). Results are essentially reinforced by digital image correlation (DIC) that allows to interpret acoustic and electromagnetic signals based on the actual strain field of the material.

|

|

|